Active measures to reduce air pollution

The making of packaging board has an impact on the air quality. We strive to limit our impact as much as possible and we do it through active environmental work, careful controls and continuous follow-up.

The solid fuel boiler produces steam and electricity

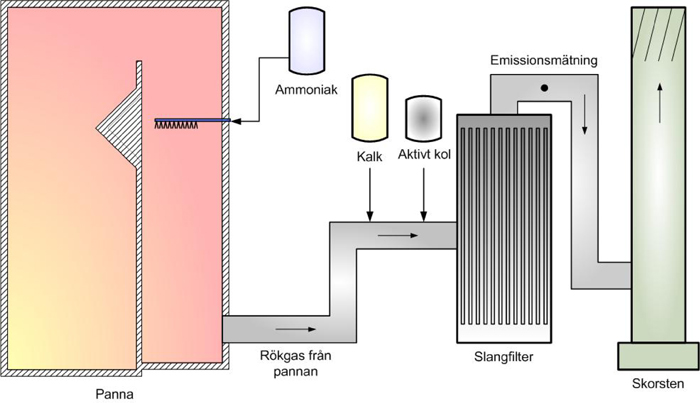

To produce steam and electricity for our packaging board manufacturing, we use a solid fuel boiler. The boiler is a grate-fired boiler with associated steam turbine and generator for electricity production. The boiler is operated as a co-incineration plant and the fuel consists of recovered wood, industrial waste and reject.

Careful flue gas purification

The flue gases from the solid fuel boiler are purified in several steps. First, the flue gases are led through textile hose filters that provide very good dust removal. Before the hose filter, lime and activated charcoal are added to the flue gases to create a good separation of sulphur and other acids.

For the reduction of nitrogen oxides, the SNCR method (selective non-catalytic reduction) is used. This means that ammonia is injected into the fireplace to reduce nitrogen oxides into nitrogen and water. The ammonia emissions are measured continuously in order to optimise the reduction of nitrogen oxides and minimise the emission of ammonia.

Air emissions from the incineration process are monitored automatically by measuring equipment that is linked to an environmental reporting system. External control of our air emissions is executed continuously. Calibration is done annually in addition to periodic measurements and comparative control.

Internal control and reporting

Based on the external conditions Fiskeby has received, an internal control program has been designed. The program describes how environmental controls are to be conducted, with which methods, how often, and how follow-up, calibration and reporting to authorities is supposed to be carried out. The reporting procedure takes place every month to the county administrative board and in an annual environmental report.