Manufacturing with sustainability in mind

In Fiskeby you will find one of Europe’s most eco-friendly mills for production of recovered fibre-based board. We are also one of the few packaging board manufacturers in the world to have an in-house extruder for plastic coating of board.

Cartonboard production

Fiskeby is the only manufacturer of recovered fibre based board (white lined chipboard) in Scandinavia. Our product is manufactured from 100% recovered fibre. We are also the only mill in Scandinavia that accepts used plastic coated cartonboard such as milk or juice packaging. The production capacity in Fiskeby is 170,000 tonnes of cartonboard per year.

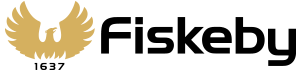

The recycled cartonboard that we receive gets ground and sent into a 40 metre long drum. By adding plain water, the drum separates plastic from paper fibre in, for example, milk packaging. The paper fibre becomes raw material in our board production while the plastic is incinerated in our energy plant along with other bioproducts.

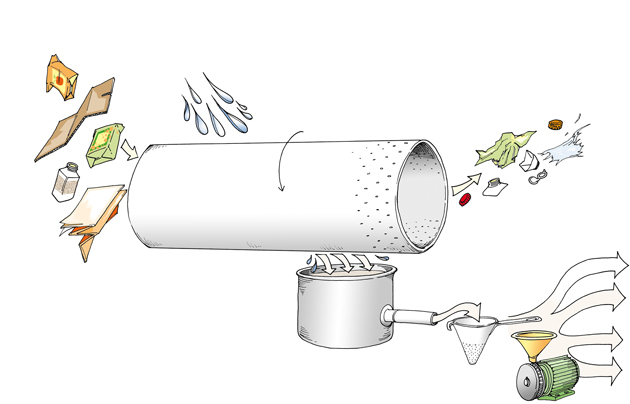

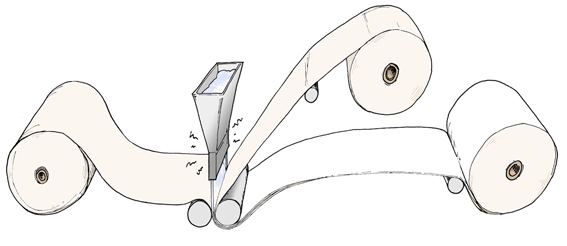

Our packaging board consists of four layers with different characteristics. Once the stock has been put into the four layers, it is compressed. Subsequently, the board is dried with the help of steam from our energy plant and finally coated to obtain a bright and even surface.

Finishing department

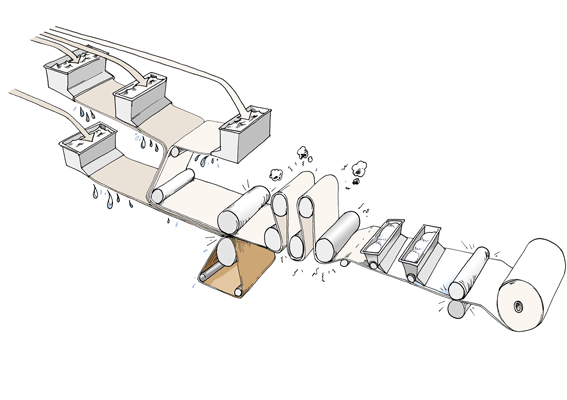

In the finishing stage, the board is cut into sheets or smaller rolls depending on the customer’s preferences. The trimmed sheets are then placed on pallets, packaged and fitted with labels. Just to be sure, we conduct quality checks at several stages during the process.

In the finishing department there is also an extrusion laminating machine. The extruder coats the board with polyethylene or a metallised polyester foil for protection against possible fatty and moist contents within the carton.

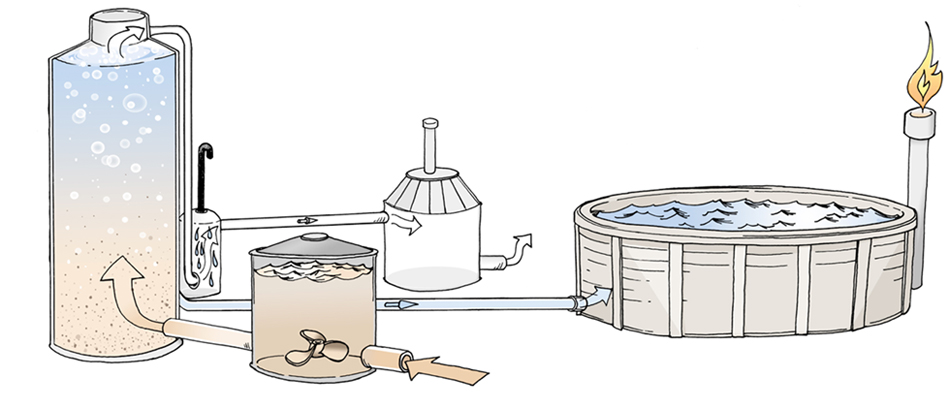

Biogas plant

Fiskeby’s biogas plant produces climate-neutral biogas from process waste water. The new biogas plant came into force in 2015 and relieves our other water purification plant. The increased purification capacity reduces our environmental impact and provides potential for extended packaging board production.

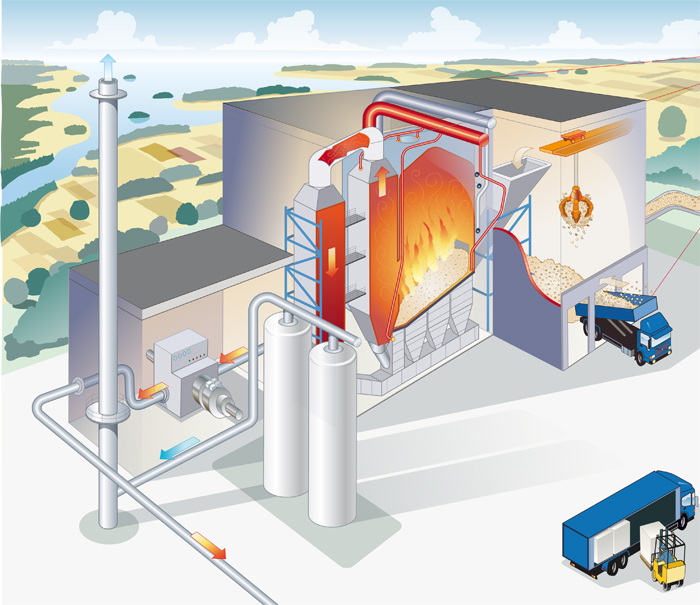

Energy production

A new solid fuel boiler was inaugurated in Fiskeby in 2010. The boiler provides all the steam used in the production of our packaging board and about 30% of our electricity needs. The fuel consists of 40% reject, 45% industrial waste and 15% recovered wood fuel.